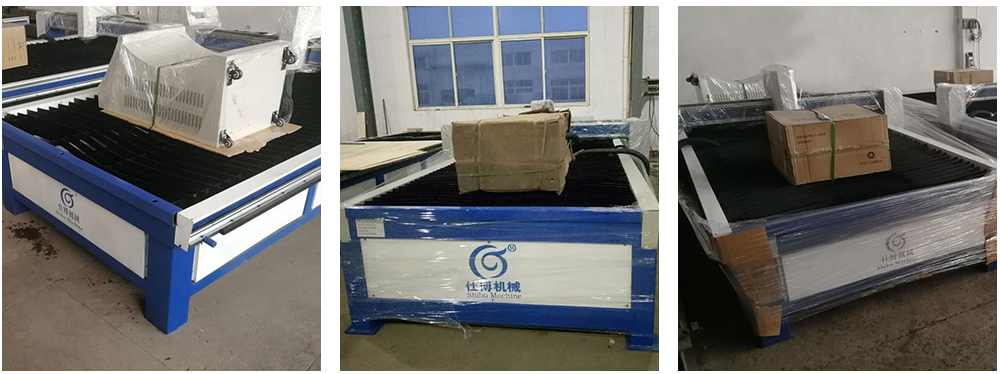

CNC Plasma Cutting Machine Air Duct Blanking Machine

Desktop CNC desktop plasma cutting machine is a CNC equipment for metal sheet cutting. It can realize cutting of various metal materials according to any pattern. The roughness of the kerf can reach 25 (▽3), and the kerf surface after cutting generally does not require surface processing. It has the advantages of high degree of automation, convenient use, high precision, high reliability, easy operation and maintenance, etc. Equipped with 7 "VGA LCD monitor, the system has automatic diagnosis function!

The plasma cutting machine is mainly composed of three parts, namely ---- electric control cabinet, bed and plasma power supply. The electric control cabinet is composed of numerical control system, servo system and other electrical components. We usually choose the more mature and reliable Beijing Star Peak SF-2012AH numerical control system, and the servo uses Panasonic AC servo. Then, the large-scale CNC clamps and fine-milling at one time, and after installing the guide rail, the guide rail is used as the benchmark, and our special pneumatic grinder is fixed on the slider, and the slider is pushed to grind the mounting surface of the rack to ensure the guide rail. parallel to the rack between the two.

| Plasma cutting thickness | ≤6.00mm |

| Lateral span | 2200mm |

| Cutting torch lift height | 0-90mm |

| Effective cutting width | 1500mm |

| Cutting speed | 0-8000mm/min |

| Longitudinal guide rail length (Guide surface finish Ra≤3.2μm) | 4500mm |

| Cutting power | 4kw |

| Effective cutting length | 4000mm |

| Plasma power supply | Chengdu Huayuan 63A |

| Control system | Beijing Star Peak SF-2012AH CNC system |

Português

Português